Description

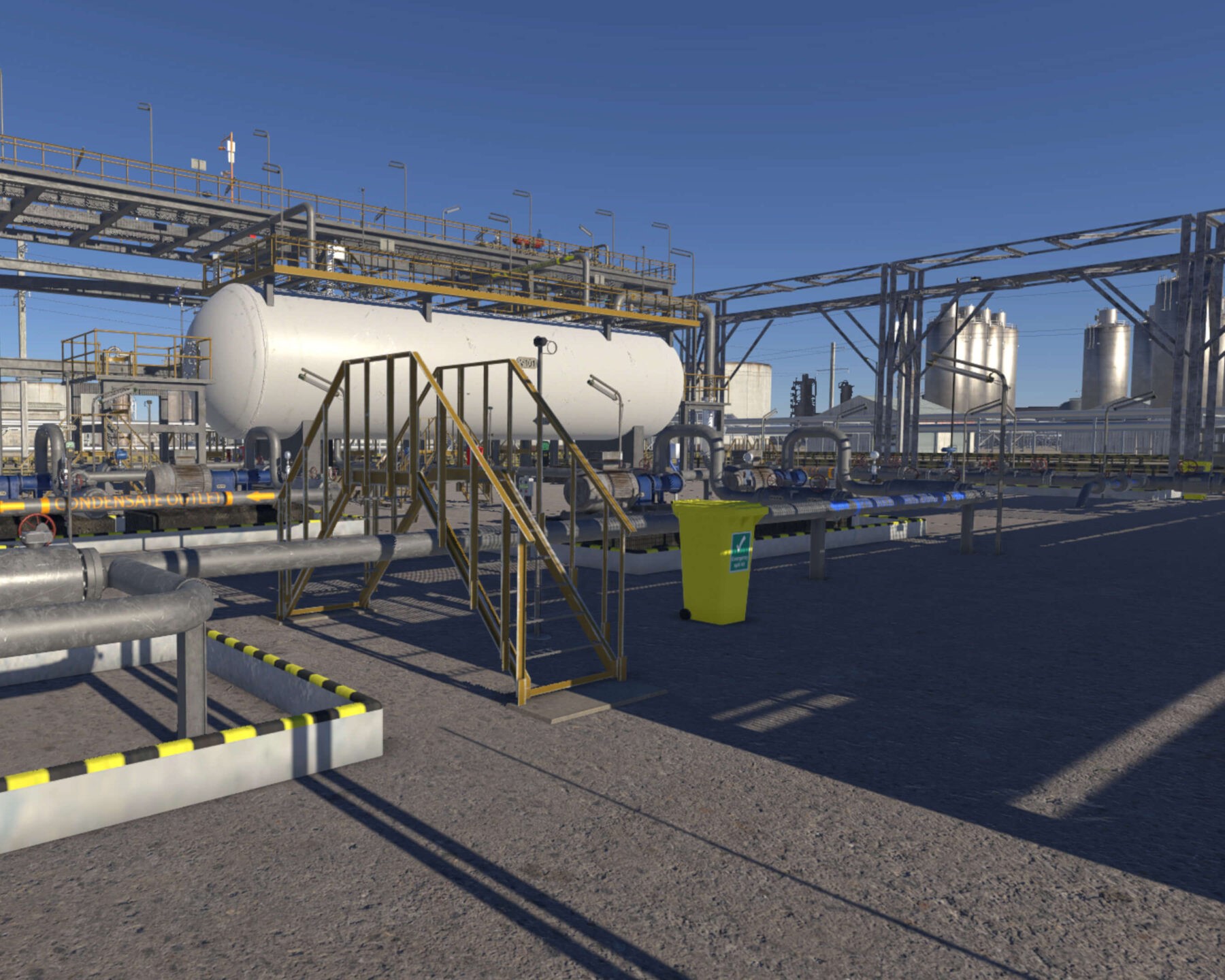

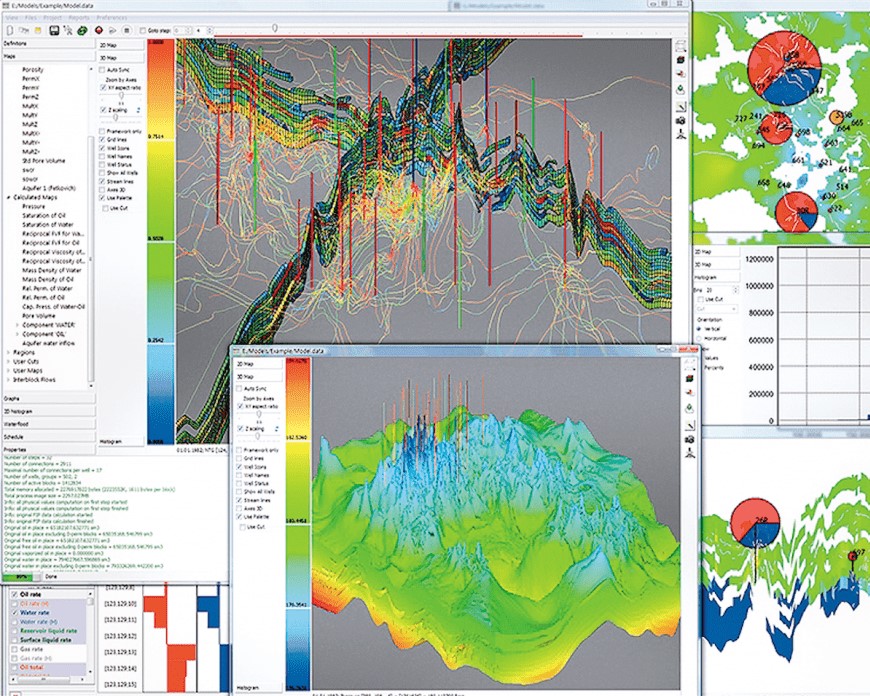

Virtual Refinery Process Simulators offer a comprehensive digital representation of refinery operations, enabling engineers, operators, and trainees to study, optimize, and manage complex chemical processes safely and efficiently. These simulators model critical refinery units such as distillation columns, hydrocrackers, reformers, heat exchangers, and separators, replicating real-world chemical reactions, fluid dynamics, heat transfer, and energy consumption. By creating an interactive, virtual environment, the simulator allows operators to visualize process flows, monitor equipment performance, and predict the effects of parameter adjustments on production efficiency, product quality, and safety. One major application is operator training; personnel can learn to manage start-ups, shut-downs, routine operations, and emergency scenarios without exposing equipment or staff to risk. The simulator supports process optimization by testing different operating strategies, feedstock compositions, catalyst performance, and temperature or pressure adjustments, helping engineers identify the most efficient operational conditions. Additionally, it enables scenario-based safety analysis by simulating process upsets, equipment failures, or hazardous chemical reactions, allowing the design of preventive measures and emergency response protocols. Integration with real-time plant data ensures that simulations reflect current operational conditions, making the tool suitable for continuous improvement initiatives, energy efficiency programs, and decision support systems. By facilitating a deep understanding of complex refinery processes, virtual refinery simulators enhance operational reliability, reduce costs, minimize environmental impact, and improve the overall safety culture in refinery operations. These platforms are particularly valuable for large-scale training programs, process optimization projects, and digital twin initiatives, bridging the gap between theoretical knowledge and practical operational expertise.

Bawa –

Virtual Refinery Process Simulators drastically accelerated our operator training. The realistic scenarios built within the software eliminated costly downtime associated with live plant exercises. Their support team was incredibly responsive, ensuring smooth integration and tailoring simulations to our specific unit operations. A solid investment.

Innocent –

Virtual Refinery Process Simulators’ allowed our team to proactively identify and mitigate bottlenecks in our crude unit, shaving crucial downtime. The simulations directly translated to a 7% increase in throughput. Excellent support; quick response times and practical, implementable solutions.

Shafaatu –

Virtual Refinery Process Simulators have been transformative. Our training time reduced by 30% thanks to the realistic scenarios. The team’s quick support helped us customize simulations to our specific crude slate, resulting in noticeable yield improvements almost immediately. A truly valuable tool.

Umar –

Virtual Refinery Process Simulators fundamentally changed our training program. Complex scenarios, previously too risky for live drills, are now safe and repeatable. The team’s responsiveness in customizing the simulator to our specific unit was exceptional, directly leading to a 15% reduction in incident reports during commissioning.

Barnabas –

Virtual Refinery Process Simulators’ drastically cut our operator training time. The interactive simulations highlighted critical process bottlenecks we hadn’t identified in real-world scenarios. Excellent technical support ensured seamless integration, resulting in faster troubleshooting and significantly improved plant efficiency.