Description

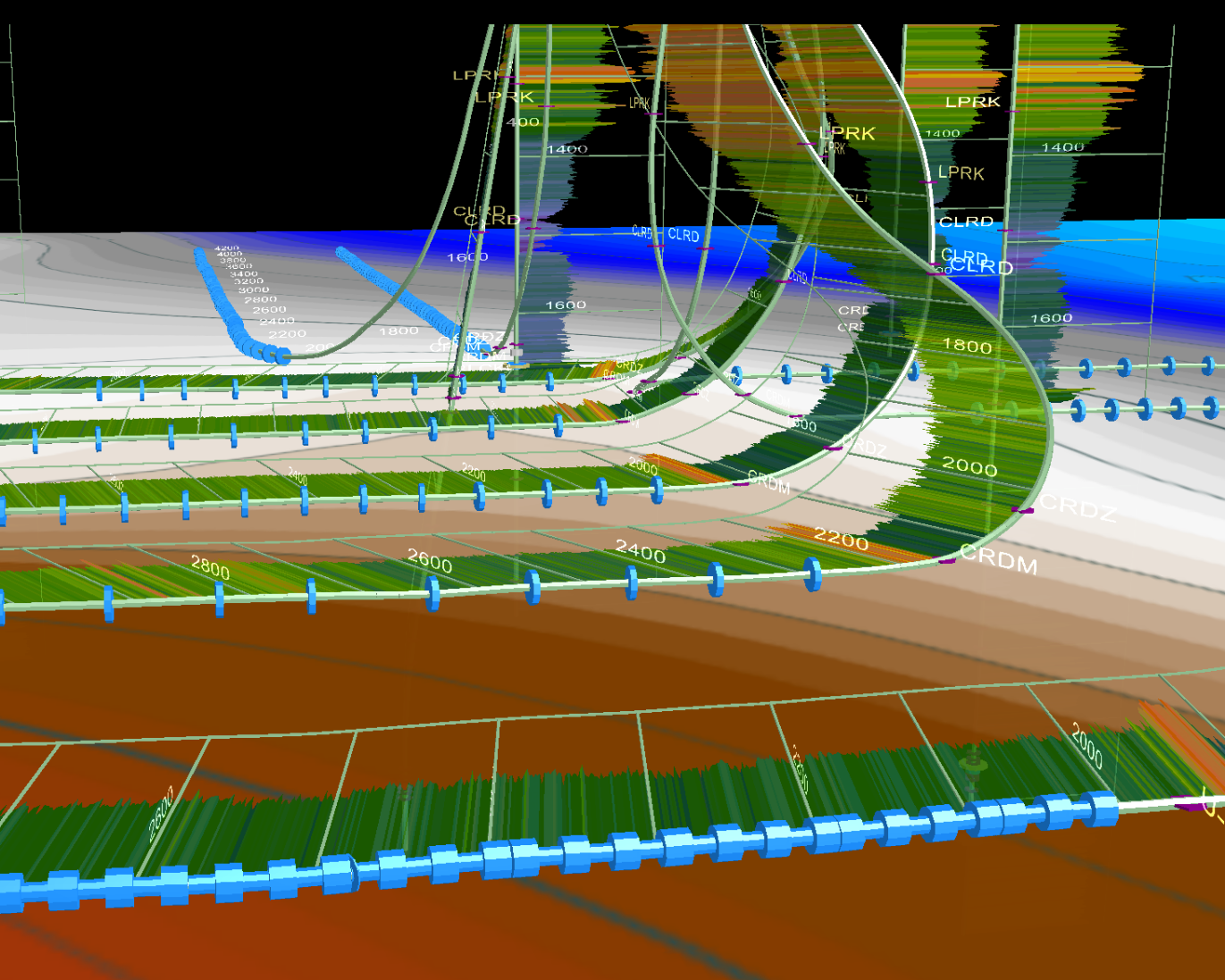

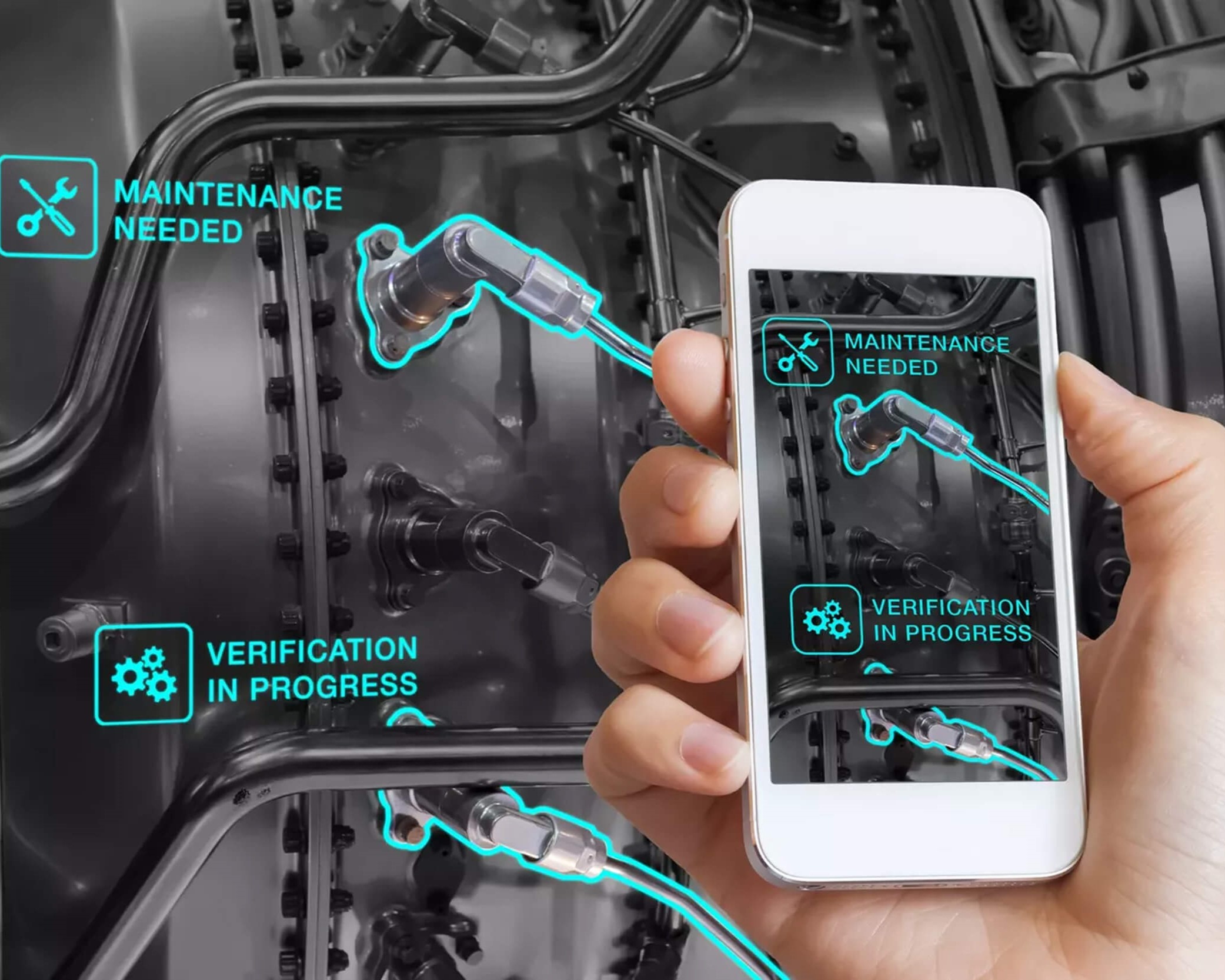

Interactive Equipment Operation Simulators provide a digital platform for oil and gas personnel to learn, practice, and optimize the operation of complex machinery, including drilling rigs, pumps, compressors, and processing units. These simulators replicate the physical and operational behavior of equipment, allowing trainees to perform routine operations, maintenance procedures, and emergency interventions in a safe, controlled virtual environment. By providing hands-on experience without the risk of damaging expensive equipment or compromising safety, these simulators significantly reduce training costs and operational risks. The system incorporates realistic controls, instrumentation, and feedback mechanisms, allowing users to understand equipment response, operational limits, and performance metrics. Trainees can explore different operational scenarios, troubleshoot malfunctions, and practice corrective measures, enhancing problem-solving abilities and decision-making skills. Performance analytics provide insight into procedural adherence, efficiency, and reaction times, enabling trainers to assess competency and guide improvement. Integration with operational manuals, standard operating procedures, and safety protocols ensures that training aligns with organizational requirements and industry regulations. Additionally, interactive simulators can support scenario-based planning, allowing engineers to evaluate the impact of operational changes on equipment performance and production outcomes before implementation. By improving technical proficiency, operational readiness, and safety awareness, Interactive Equipment Operation Simulators enhance workforce capability, reduce downtime, and increase overall operational efficiency in oil and gas operations. They bridge the gap between theoretical knowledge and real-world application, ensuring personnel are well-prepared for complex, high-risk equipment operation scenarios.

Ebere –

Implementing Interactive Equipment Operation Simulators drastically cut our startup time on new drilling rigs. The team’s responsiveness in tailoring scenarios to our specific equipment was exceptional. Improved operator confidence translated directly into smoother, faster, and safer commissioning – a significant ROI driver.

Adams –

Our team’s proficiency on new separator models skyrocketed after implementing Interactive Equipment Operation Simulators. The risk-free environment allowed them to experiment, troubleshoot, and master procedures quickly. Communication with the support team was seamless, ensuring smooth integration and addressing specific operational quirks we encountered.

Oluwafemi –

Interactive Equipment Operation Simulators drastically reduced our equipment startup errors. The team now confidently handles complex procedures thanks to the realistic scenarios. Excellent simulator build quality and responsive support ensured a smooth integration into our training program, boosting overall operational competence.

Gambo –

Interactive Equipment Operation Simulators” have been a game-changer for our training program. The realistic simulations drastically reduced equipment downtime caused by operator error. The support team was incredibly responsive, and the quality of the visuals is top-notch, making the learning curve surprisingly smooth.