Description

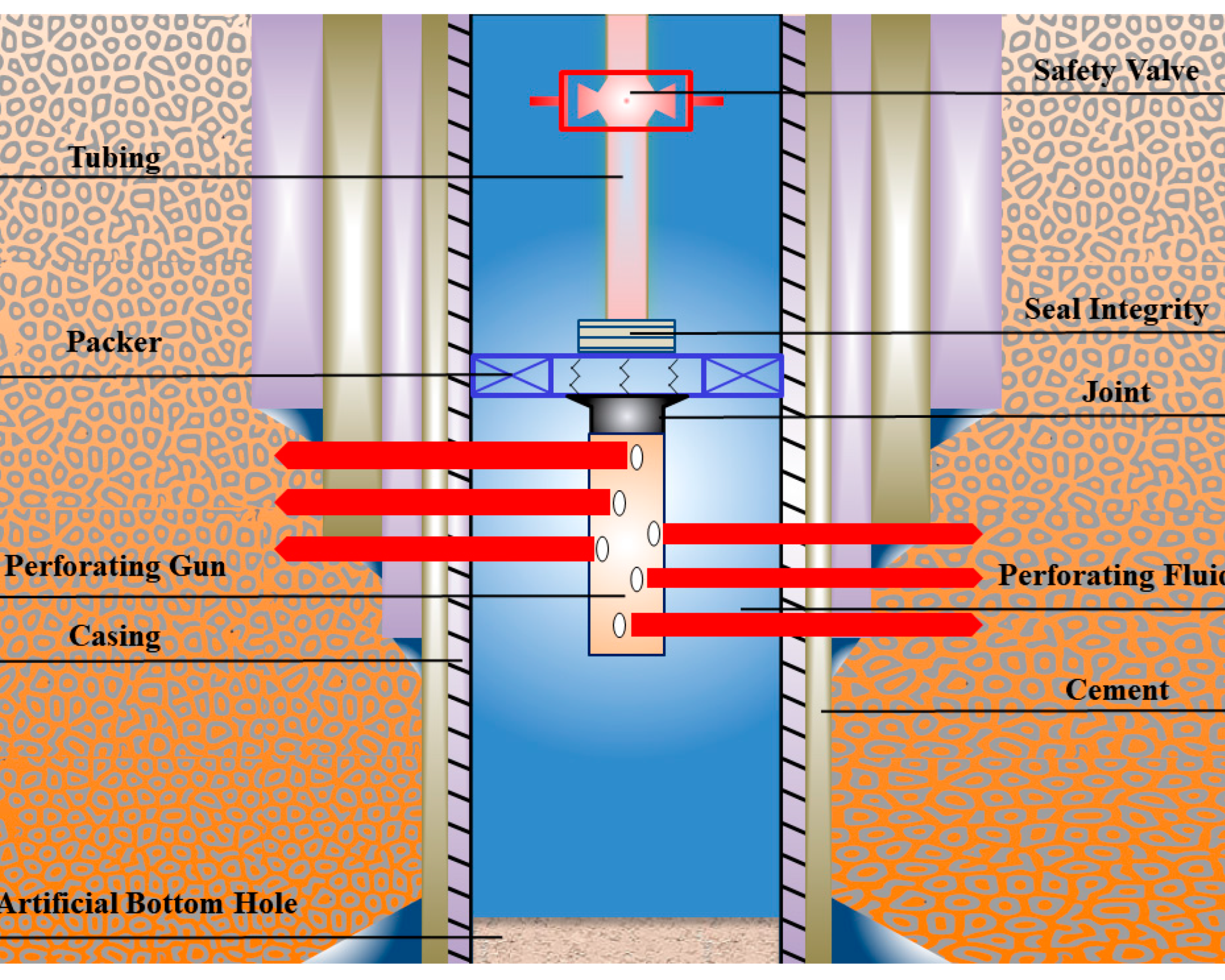

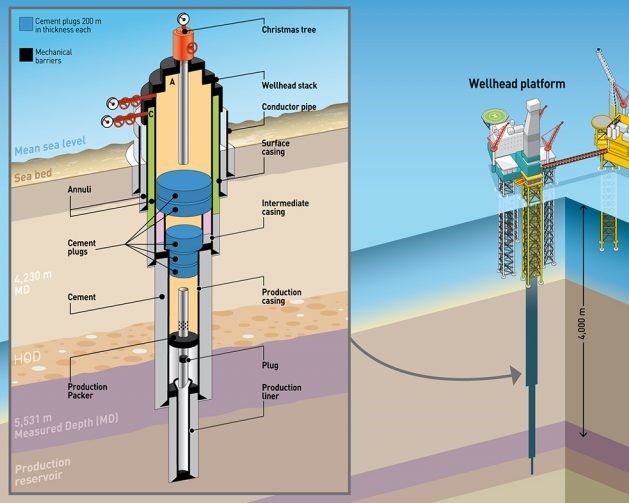

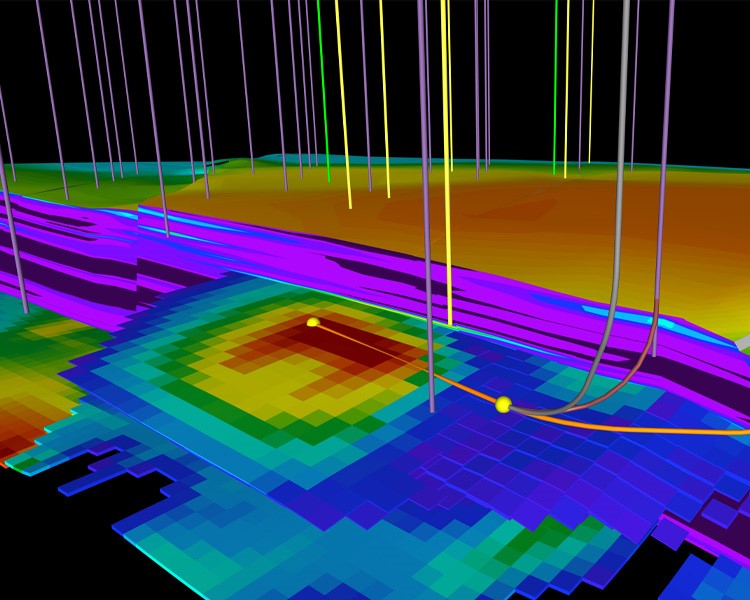

Downhole Tool Performance Simulators provide a virtual environment to model, analyze, and optimize the behavior of tools used in the wellbore, including drill bits, mud motors, stabilizers, measurement-while-drilling (MWD) instruments, and other downhole equipment. These simulators combine physics-based modeling, real-world operational data, and formation properties to replicate the mechanical, thermal, and hydraulic conditions encountered by tools during drilling. Engineers and operators can assess how different tools will respond to variables such as weight on bit, rotational speed, torque, vibration, temperature, and formation hardness, allowing for informed selection and configuration of downhole equipment. By identifying potential tool failures, excessive wear, or performance inefficiencies before deployment, the simulator reduces downtime, minimizes operational risks, and improves overall drilling efficiency. The system also supports scenario analysis, enabling users to test alternative drilling strategies, mud compositions, and tool sequences in complex well geometries or challenging formations. Training applications are also significant; operators and engineers can gain experience handling tools in virtual environments, understanding operational limits and performance characteristics without risking expensive equipment or wellbore integrity. Integration with real-time drilling data enhances predictive capabilities, allowing continuous optimization of tool performance and adjustments to drilling parameters on the fly. By reducing uncertainty, improving tool selection, and increasing operational efficiency, Downhole Tool Performance Simulators contribute to safer, more cost-effective, and technically optimized drilling operations. They are a key enabler of modern digital oilfield initiatives, supporting data-driven decision-making and innovation in well construction and maintenance.

Oluwatosin –

Before ‘Downhole Tool Performance Simulators,’ optimizing BHA configurations felt like guesswork. Now, we confidently predict tool performance across varied formations. The simulator’s accuracy reduced NPT significantly, and their support team clarified complex modeling nuances instantly, resulting in faster, better-informed drilling decisions.

Joel –

Downhole Tool Performance Simulators” revolutionized our drilling program design. We accurately predicted bit performance in complex formations, slashing unplanned trips. The detailed simulations and responsive support team enabled us to optimize BHA configurations, exceeding our ROP targets. Quality execution from start to finish.

Saliu –

Downhole Tool Performance Simulators’ drastically cut our non-productive time. By realistically predicting tool behavior across formations, we preemptively avoided two costly motor failures in the Permian. Support was exceptionally responsive, and the integrated data visualization streamlined our decision-making process immediately.