Description

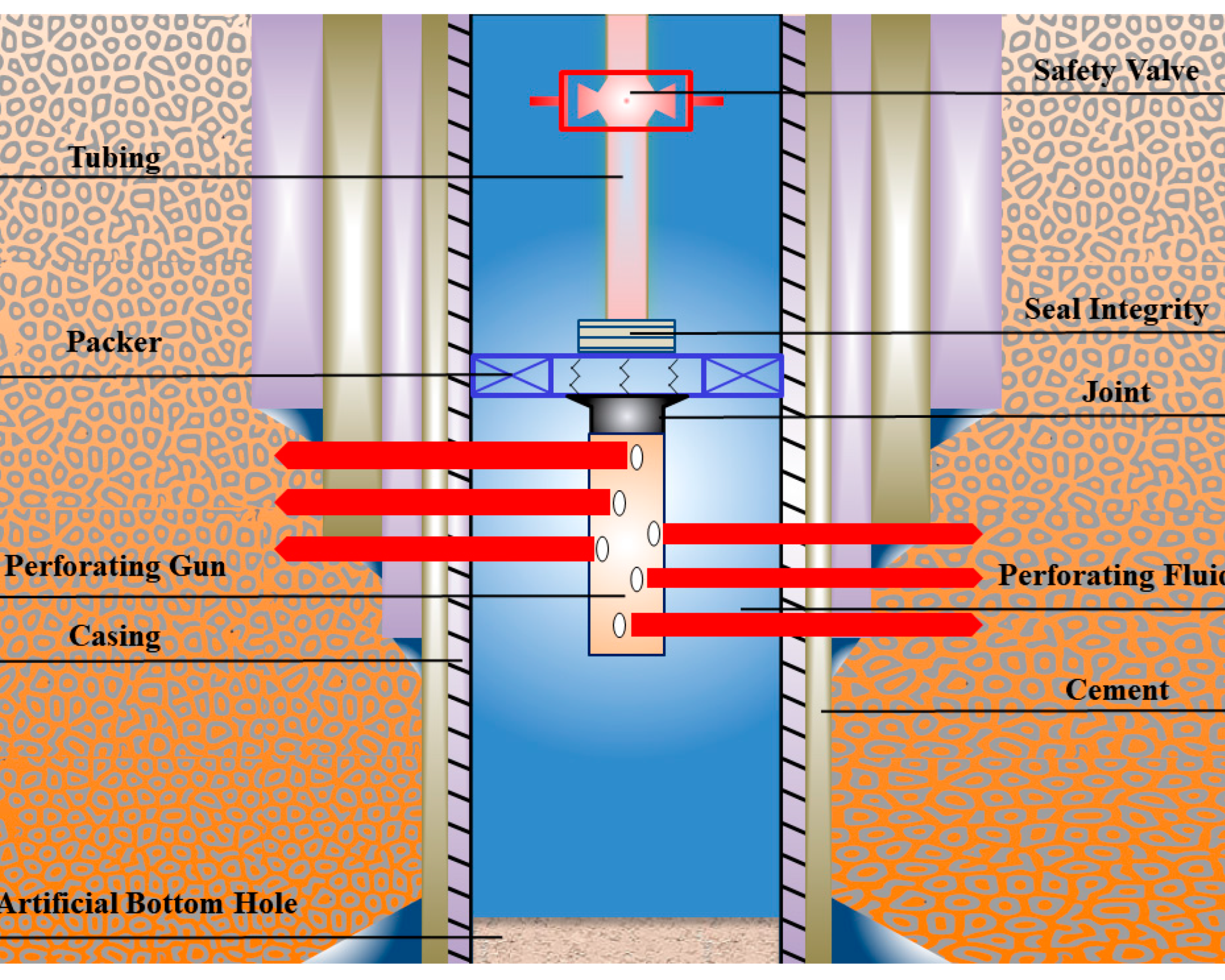

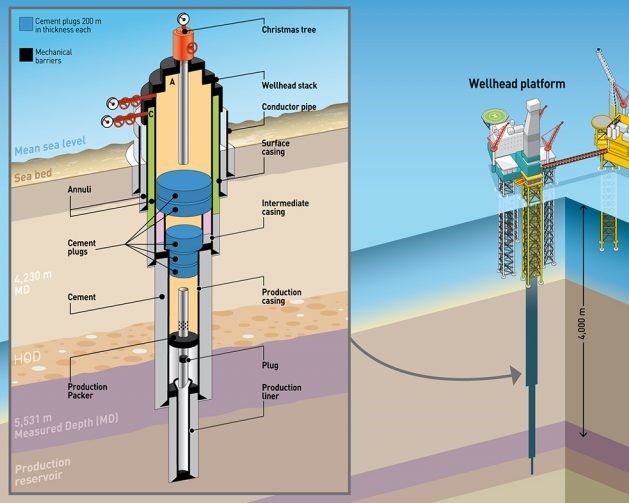

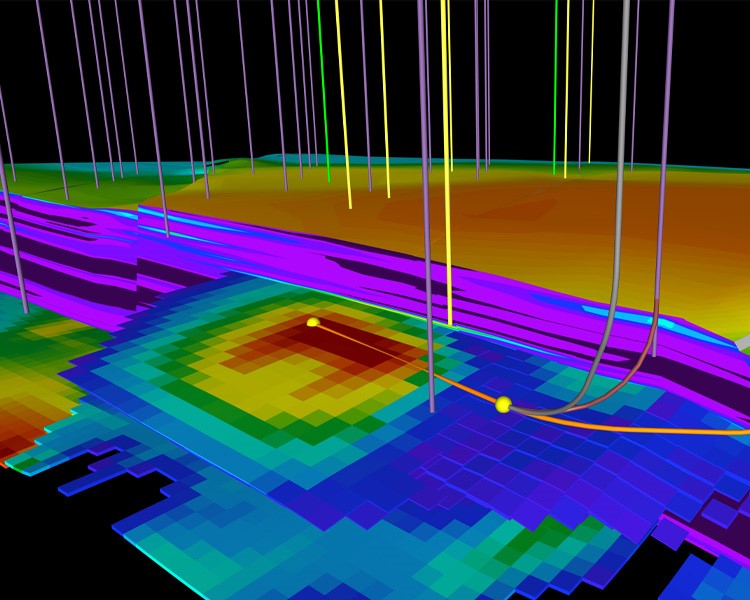

The Digital Twin of Drilling Rigs represents a transformative approach in the oil and gas sector, allowing operators to bridge the gap between physical rig operations and virtual simulations. Essentially, a digital twin is a comprehensive, real-time virtual replica of an actual drilling rig, integrating data from sensors, SCADA systems, and IoT devices to create a precise representation of the rig’s performance, structural integrity, and operational status. By simulating complex drilling scenarios in a digital environment, companies can predict equipment failures, optimize operational efficiency, and minimize downtime. This virtual model captures everything from drill string dynamics, pump performance, and torque and drag calculations to mud circulation and vibration analysis. One of the most significant advantages is predictive maintenance. By analyzing the digital twin, operators can foresee wear and tear on critical components, plan maintenance schedules proactively, and reduce unplanned operational halts. The system also enhances safety; by simulating potential high-risk events, such as equipment malfunctions or adverse geological conditions, teams can design mitigation strategies without exposing personnel to danger. Moreover, it facilitates better decision-making through data visualization, analytics dashboards, and scenario modeling, enabling teams to optimize drilling parameters for maximum efficiency. Digital twins also support collaborative operations, as engineers, geologists, and drilling managers across different locations can interact with the same virtual model, ensuring consistent strategies and reduced miscommunication. Furthermore, integration with machine learning algorithms allows for continuous improvement in operational efficiency, predicting equipment behavior based on historical data and adapting strategies accordingly. As drilling projects grow more complex, the digital twin becomes a cornerstone of intelligent operations, helping companies reduce costs, enhance safety, and extend the lifecycle of rigs and associated equipment. Overall, this tool is essential for modern oil and gas operations seeking to combine cutting-edge digital technology with practical field experience.

Monsurat –

Digital Twin of Drilling Rigs” fundamentally changed our approach to maintenance planning. The real-time visualization and predictive alerts flagged potential equipment failures *before* they happened, minimizing downtime and saving us considerable operational costs. Their support team was remarkably responsive and technically adept.

Isa –

Digital Twin of Drilling Rigs” revolutionized our offshore maintenance scheduling. Unexpected equipment failures plummeted after implementing the predictive analysis features. The team’s prompt support and clear communication ensured seamless integration. Downtime significantly decreased, exceeding our ROI projections.

Godswill –

Digital Twin of Drilling Rigs” immediately reduced our downtime. Previously reactive, we’re now proactively addressing potential failures thanks to its predictive maintenance capabilities. The visualization is exceptional, and the support team’s prompt responses truly maximized the platform’s value for our operations.

Anietie –

Implementing the Digital Twin of Drilling Rigs drastically cut our non-productive time. We anticipated equipment failures we’d have missed otherwise. The team’s communication was seamless, and their proactive support ensured a flawless integration. The accuracy of the digital twin is truly impressive.