Description

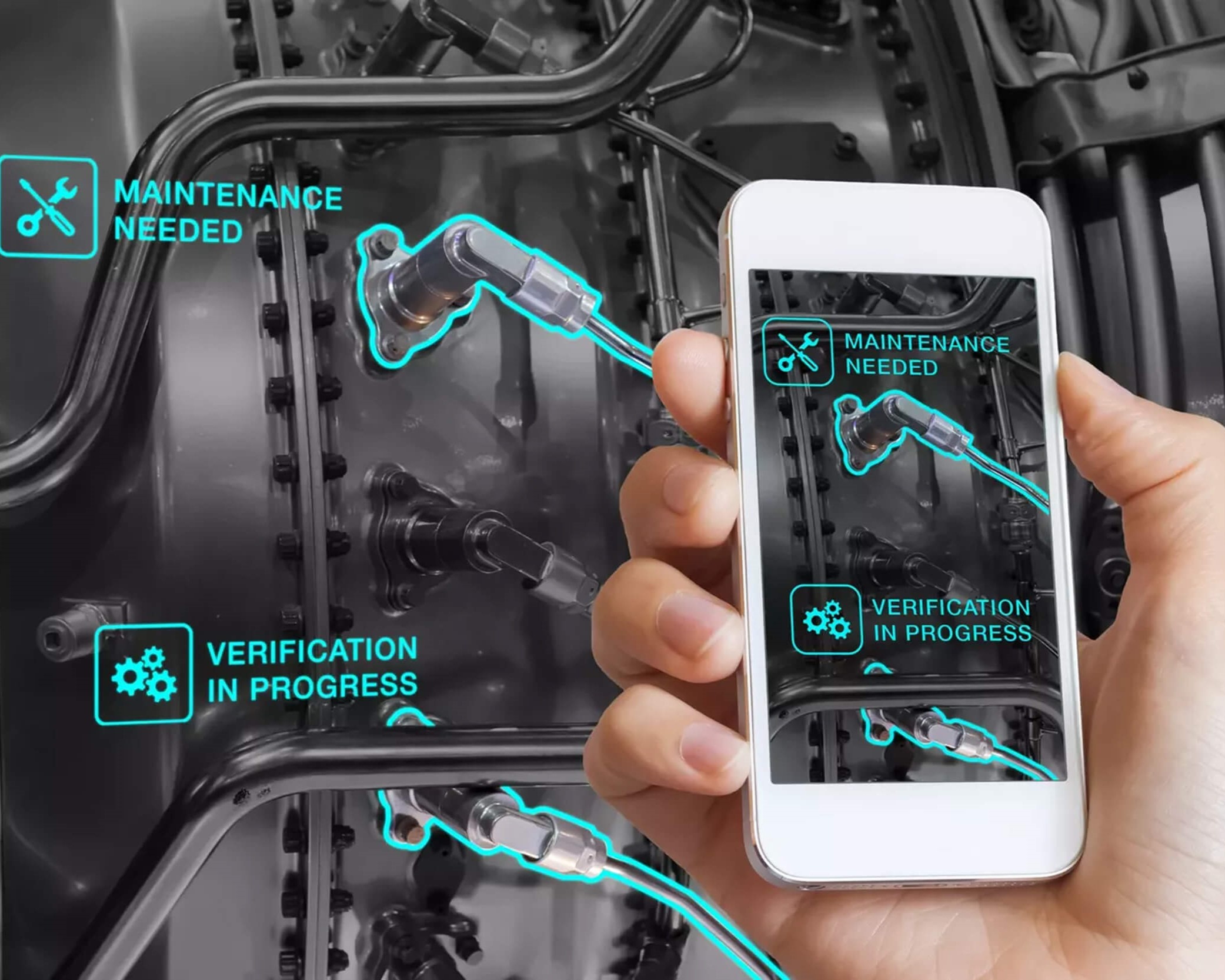

Augmented Reality Maintenance Guides leverage AR technology to provide oil and gas maintenance personnel with real-time, interactive instructions overlaid directly onto physical equipment. These guides enable users to visualize components, understand complex assemblies, and follow step-by-step procedures for inspection, troubleshooting, and repair without the need for extensive manuals or on-site expert supervision. The AR system can highlight critical components, display operational parameters, and provide warnings or alerts for potential hazards, improving accuracy, efficiency, and safety. One of the primary benefits is reduced maintenance errors, as personnel can follow precise, visually guided procedures, minimizing the risk of improper handling or missed steps. The guides are especially valuable for complex machinery, subsea equipment, or remote sites, where expert guidance may be limited. Integration with enterprise maintenance systems allows real-time tracking of work orders, component status, and completion verification, facilitating accountability and operational transparency. AR Maintenance Guides also support training, allowing new personnel to gain hands-on experience in a virtual overlay environment while learning standard operating procedures. Scenario-based simulations can demonstrate common faults, preventive maintenance tasks, and emergency interventions, enhancing skill retention and operational readiness. By combining real-world visibility with virtual instructions, these guides optimize maintenance workflows, reduce downtime, enhance safety, and improve overall asset reliability. In modern oil and gas operations, where equipment complexity and operational risks are high, Augmented Reality Maintenance Guides are indispensable tools for efficient, safe, and accurate maintenance management.

Chukwu –

Implementing Augmented Reality Maintenance Guides drastically cut our turbine overhaul times. The precise, overlaid instructions eliminated ambiguity, minimizing errors. Beyond the technology, their team’s rapid response to our platform customization needs and ongoing support have been invaluable, yielding a tangible improvement in efficiency.

Iyabo –

Augmented Reality Maintenance Guides have revolutionized our turbine maintenance. Downtime is significantly reduced; complex tasks, now visually guided, are performed correctly the first time. The team’s responsiveness to our specific equipment needs and immediate support sealed the deal. A truly innovative solution.

Ijeoma –

Augmented Reality Maintenance Guides’ revolutionized our turbine overhauls. Complex tasks became intuitive, slashing downtime by 20%. The AR overlays were precise, and the support team promptly addressed our unique equipment configurations. A game-changer for remote site efficiency.

Balikis –

Augmented Reality Maintenance Guides have revolutionized our offshore platform maintenance. Complex tasks are now completed faster with fewer errors. The reduced downtime alone justified the investment. Excellent execution, prompt support and clear team communication made implementation seamless. A game-changer for efficiency.

Omowumi –

Implementing Augmented Reality Maintenance Guides slashed our turbine downtime by 20%. Complex overhauls are now intuitive, minimizing errors. The visual clarity is outstanding, and the support team quickly resolved our initial integration questions, ensuring a seamless rollout. A game-changer for efficiency.