Description

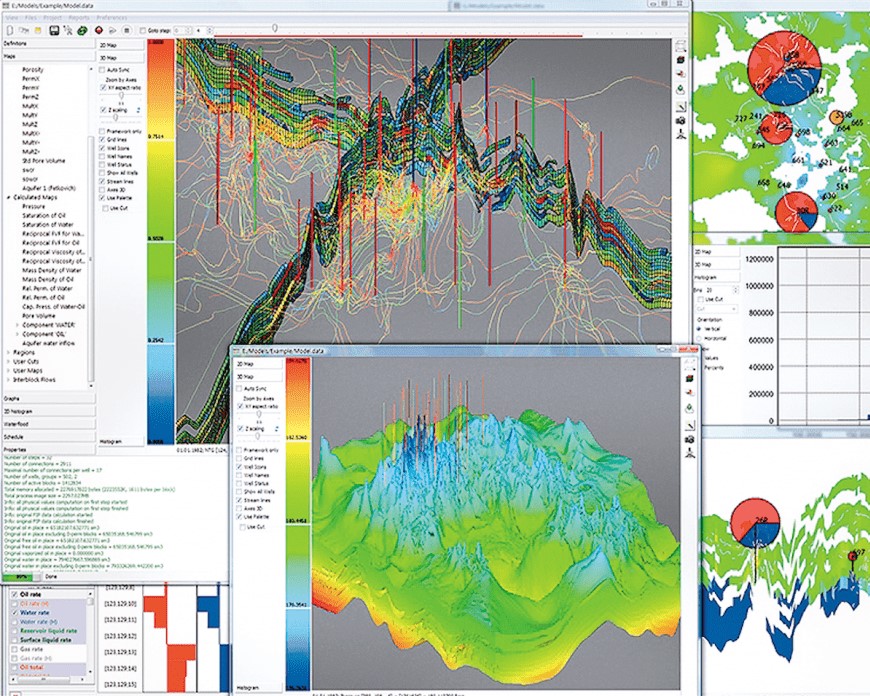

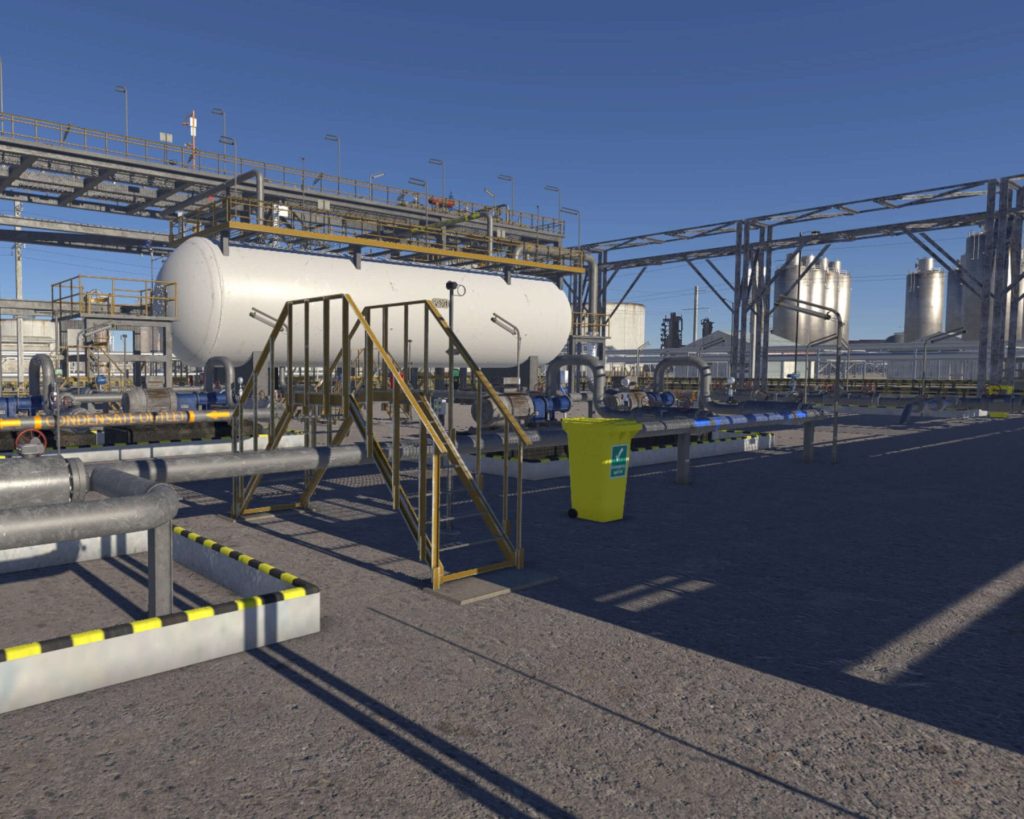

Pipeline Integrity Monitoring Systems are advanced technological solutions designed to ensure the safe and efficient operation of oil and gas pipelines. These systems combine sensors, telemetry, and analytical software to provide continuous, real-time monitoring of pipeline health, detecting corrosion, leaks, cracks, pressure fluctuations, and mechanical stresses that could compromise structural integrity. By collecting and analyzing data on pipeline material conditions, environmental factors, and operational parameters, these systems enable early detection of potential failures, allowing preventive maintenance and repair before critical incidents occur. One key feature of pipeline integrity monitoring is its ability to assess corrosion rates, material degradation, and weld integrity using techniques such as ultrasonic testing, smart pigging, fiber-optic sensors, and pressure/temperature monitoring. Additionally, these systems can detect external threats, including third-party interference, ground movement, and environmental hazards, enhancing pipeline security and reliability. Integration with advanced analytics and AI allows operators to prioritize maintenance actions, forecast potential issues, and optimize inspection schedules, reducing downtime and minimizing costs. The systems also support regulatory compliance by documenting inspection records, incident alerts, and safety metrics, helping operators meet stringent industry standards and governmental requirements. Pipeline integrity monitoring enhances operational safety, prevents environmental contamination from leaks, and improves the lifespan of infrastructure. In a landscape where pipeline failures can result in significant financial, environmental, and reputational damage, these systems are critical tools for proactive asset management, risk mitigation, and sustainable energy transport. They empower pipeline operators with actionable insights, real-time alerts, and predictive capabilities, ensuring consistent and safe flow of hydrocarbons across extensive networks. Overall, pipeline integrity monitoring systems represent a vital component of modern oil and gas infrastructure management, combining technology, analytics, and operational expertise to safeguard assets and people.

Isah –

Pipeline Integrity Monitoring Systems’ flagged a subtle anomaly we’d have missed. Their real-time data drastically reduced inspection downtime and improved our preventative maintenance scheduling. The quick response and insightful analysis from their team were invaluable in averting a potential rupture. We’re seeing significant cost savings.

Chidiebere –

Pipeline Integrity Monitoring Systems’ proactive approach fundamentally shifted our pipeline management. We identified a potential corrosion hot spot early, avoiding a costly shutdown and environmental incident. The team’s clear communication and responsive support were invaluable throughout the deployment. A game-changer for operational peace of mind.

Godson –

Implementing Pipeline Integrity Monitoring Systems drastically reduced our incident response time. The granular, real-time corrosion data flagged a potential failure point we’d have otherwise missed. Excellent system integration and responsive support ensured a seamless transition, improving operational uptime significantly.

Sarah –

Implementing Pipeline Integrity Monitoring Systems drastically reduced our manual inspection time. We identified a critical corrosion point previously missed, averting a potential shutdown. The team’s proactive support and clear communication made the entire process seamless. A truly valuable investment in pipeline safety.

Susan –

Pipeline Integrity Monitoring Systems has been a game-changer. We immediately saw a reduction in unscheduled downtime thanks to proactive leak detection. Their team’s prompt support and clear communication during setup were invaluable, ensuring seamless integration with our existing infrastructure.